Vapor Suppression & Odor Control

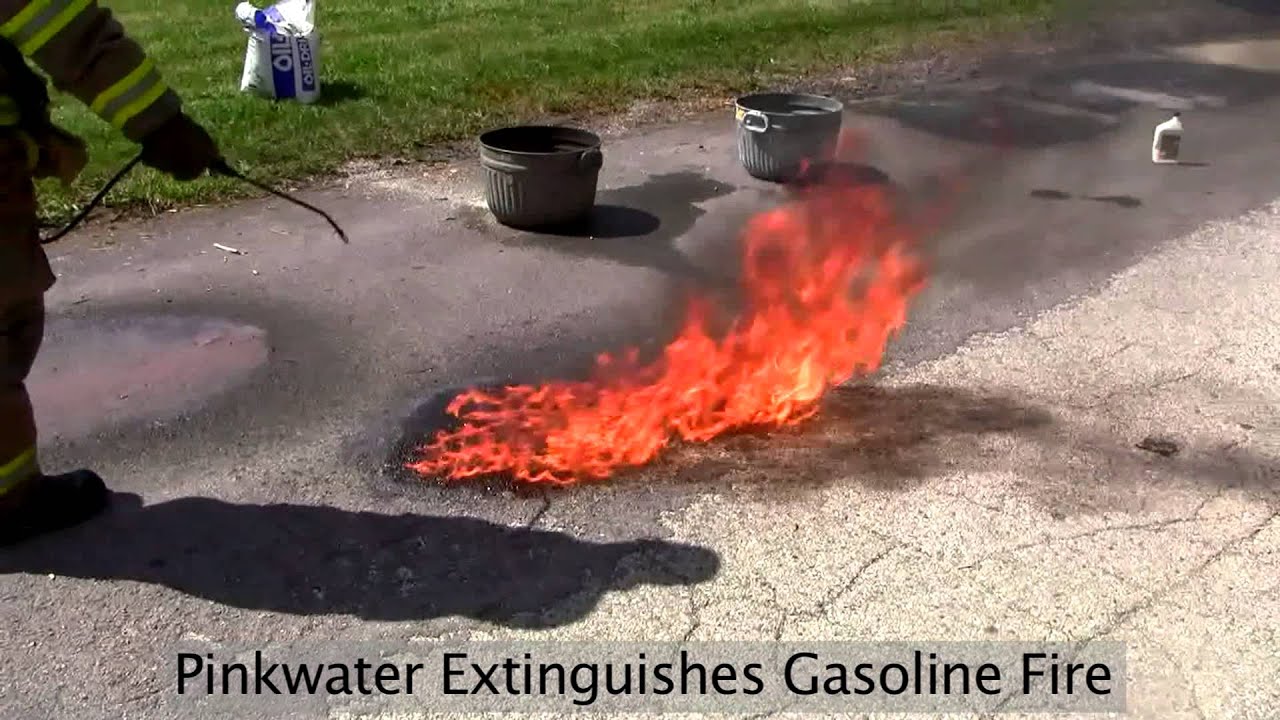

BioSolve® Pinkwater or BioSolve® Activator offer a safe, simple, cost-effective method vapor suppression and odor control.

Volatile organic compound (VOC) emissions inevitably result when excavation takes place in hydrocarbon impacted soils. The odors resulting from these emissions my simply be a public nuisance or could pose a health hazard to workers and the general public. BioSolve® Pinkwater or BioSolve® Activator offer a safe, simple, cost-effective method vapor suppression and odor control at remediation and brownfield excavation sites by suppressing VOCs at the source – on the soil surface.

Pinkwater and Activator work by encapsulating hydrocarbons and “locking” VOCs in the soil, allowing work to continue unabated. In tests conducted at Tufts University (Medford, MA) hydrocarbon VOCs were reduced by 99+% compared to treatment with water or no treatment at all. Odor suppression remained effective for almost 60 minutes before gradually returning. Pinkwater is an excellent product for most sites. For environmentally sensitive areas, Activator may be preferred as it is readily biodegradable and is formulated from ingredients on EPA’s Safer Chemical Inventory List.

| FIELD APPLICATIONS | Pinkwater | Clear | Activator | Hydrovent |

|---|---|---|---|---|

| Surfactant Enhanced Aquifer Remediation | ||||

| Aerobic Biodegradation of Impacted Soil Insitu Spill Remediation Land Farming & Biopiles | ||||

| Industrial Maintenance UST & AST Cleaning/Degassing Subfloor/Interstitular Decomntamination | ||||

| Vapor/Odor Control MGP Site & Brownfield Remediation Stabilization/Solidification Excavation in Impacted Soil | ||||

| Hydrocarbon Spill Response Spill Clean-Up Equipment Decontamination |