In-Situ Soil Remediation or Surfactant Enhanced Soil Remediation

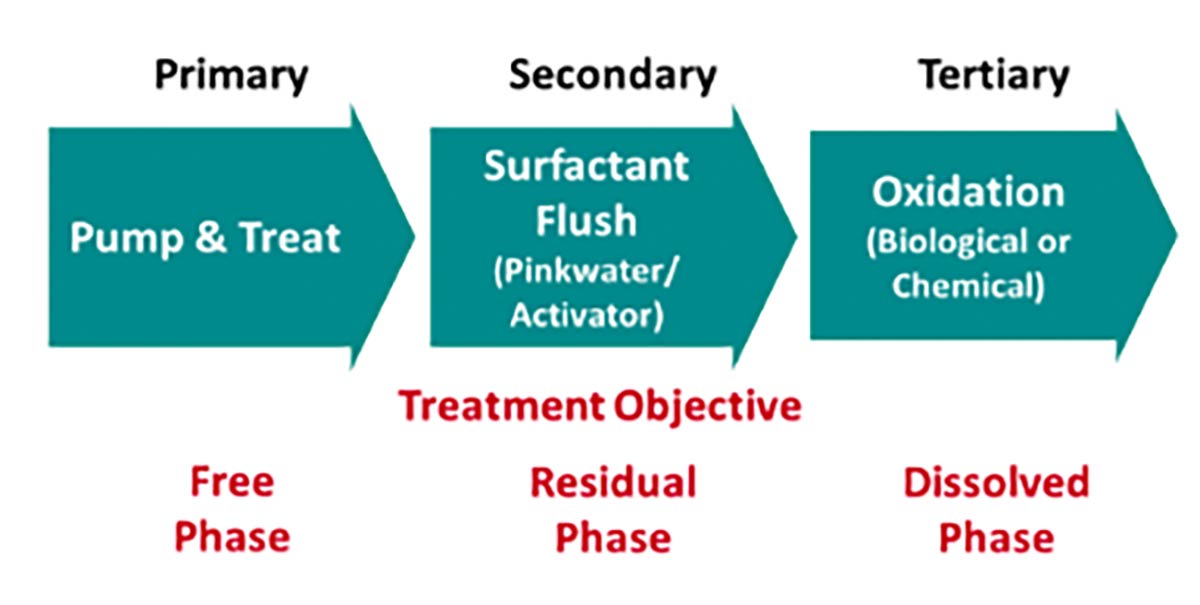

In-situ remediation for extracting hydrocarbon contamination from soil and groundwater can be thought of as a three-step process as outlined in the below.

| FIELD APPLICATIONS | Pinkwater | Clear | Activator | Hydrovent |

|---|---|---|---|---|

| Surfactant Enhanced Aquifer Remediation | ||||

| Aerobic Biodegradation of Impacted Soil Insitu Spill Remediation Land Farming & Biopiles | ||||

| Industrial Maintenance UST & AST Cleaning/Degassing Subfloor/Interstitular Decomntamination | ||||

| Vapor/Odor Control MGP Site & Brownfield Remediation Stabilization/Solidification Excavation in Impacted Soil | ||||

| Hydrocarbon Spill Response Spill Clean-Up Equipment Decontamination |