Bioremediatiion of Hydrocarbon Contaminated Soil

Landfarming: Aerobic Bioremediation

Landfarming is an above-ground remediation technology for reducing concentrations of petroleum products through aerobic bioremediation. This technology usually involves spreading contaminated soil in a thin layer on the ground and stimulating aerobic microbial activity within the soil through aeration and the addition of nutrients, surfactants and moisture.

The BioSolve® Company offers two products used to accelerate bioremediation activity: BioSolve® Activator and BioSolve® Hydrovent. Activator is a proprietary formulation of surfactants and other specialty chemicals that mobilizes oil trapped in the soil, releasing it into the aqueous phase to improve bioavailability – accelerating naturally occurring microbiological processes. Hydrovent is a formulation of bioremediation nutrients blended with Activator.

Customers have a choice of purchasing blended package with nutrients (Hydrovent) or a surfactant formulation alone (Activator), which can be applied with their own nutrients. Regardless of the choice, nutrients, in the form of nitrogen and phosphorus, are required to sustain bioremediation activity.

Under favorable conditions (involving temperature, aeration, moisture, pH, nutrients and an active microbiological colony suitable for hydrocarbon degradation), contamination levels in soil may be reduced by up to 90% in less than 45 days using aerobic bioremediation alone.

| FIELD APPLICATIONS | Pinkwater | Clear | Activator | Hydrovent |

|---|---|---|---|---|

| Surfactant Enhanced Aquifer Remediation | ||||

| Aerobic Biodegradation of Impacted Soil Insitu Spill Remediation Land Farming & Biopiles | ||||

| Industrial Maintenance UST & AST Cleaning/Degassing Subfloor/Interstitular Decomntamination | ||||

| Vapor/Odor Control MGP Site & Brownfield Remediation Stabilization/Solidification Excavation in Impacted Soil | ||||

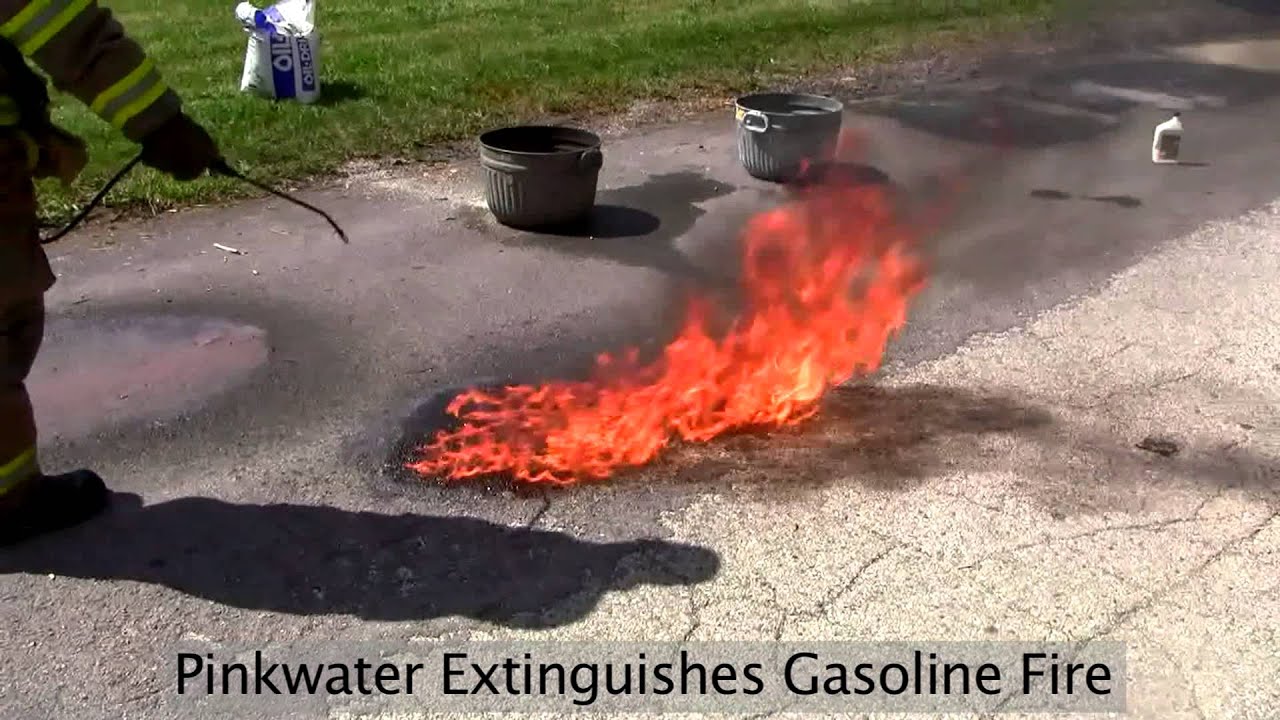

| Hydrocarbon Spill Response Spill Clean-Up Equipment Decontamination |